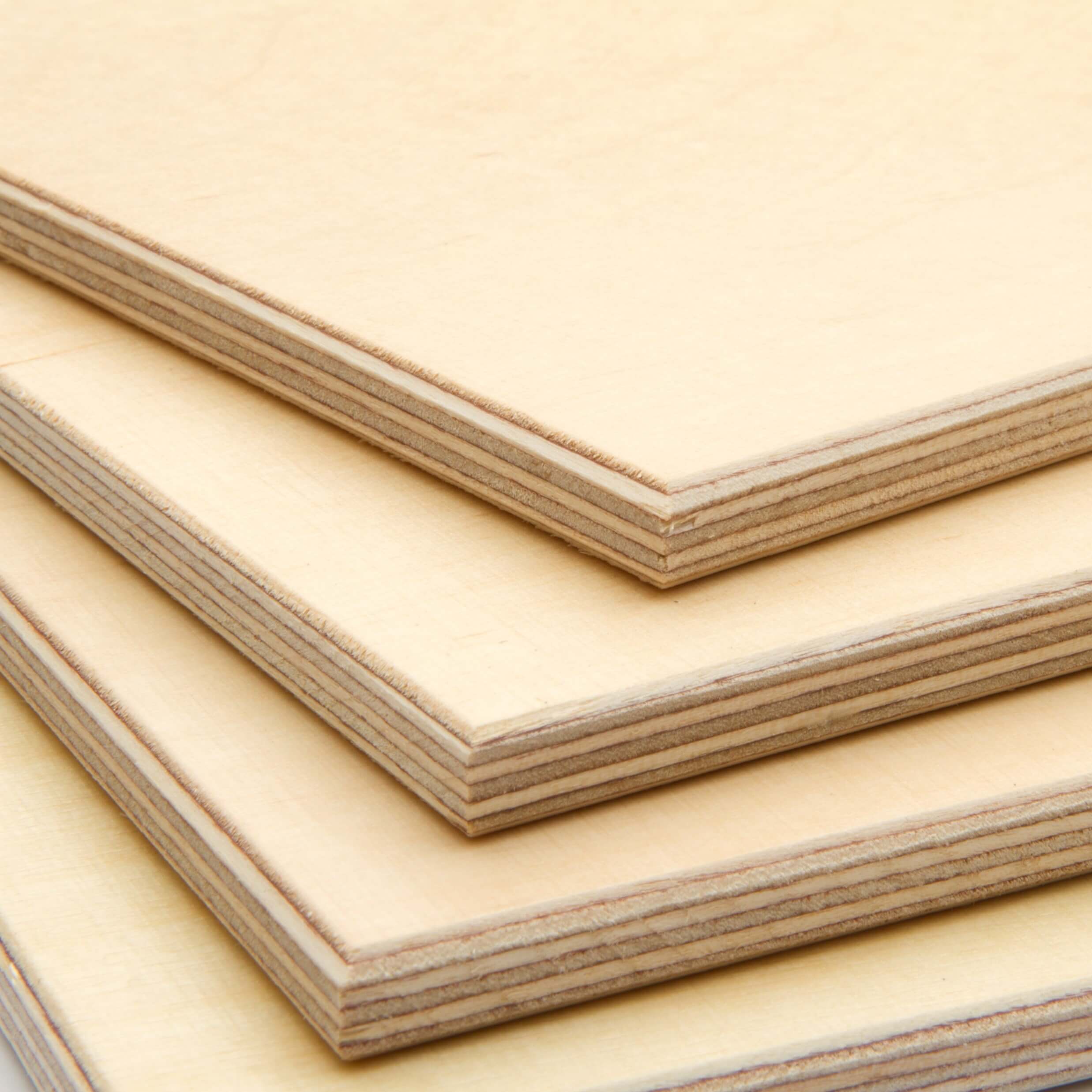

Specialist Birch Plywood

In this Specialist Birch Plywood section, you will find a range of performance-oriented poly coated, phenolic ply overlaid and lacquered plywood products. These products are sourced from modern mills across Europe, offering durable and technical wood panel solutions.

Our plywood products have a variety of face options ranging from laser plywood and birch veneer to differing colours like brown, grey and black plywood. Our range comes with a variety of patterns and textures to suit your needs.

This range of ‘special products’ are suitable for a variety of end applications – including staging, events floors, flight cases, container floors, formwork, and as slip-resistant flooring in vehicles. These panels are available with either FSC® or PEFC certification.

- Key:

Typically available 'Ex-stock'

Typically available 'Ex-stock' Available via Forward Order

Available via Forward Order Not Available

Not Available

Primed (Grey)

Birch Plywood that has been primed with a grey coloured primer. Suitable for interior and exterior use, painted or unpainted

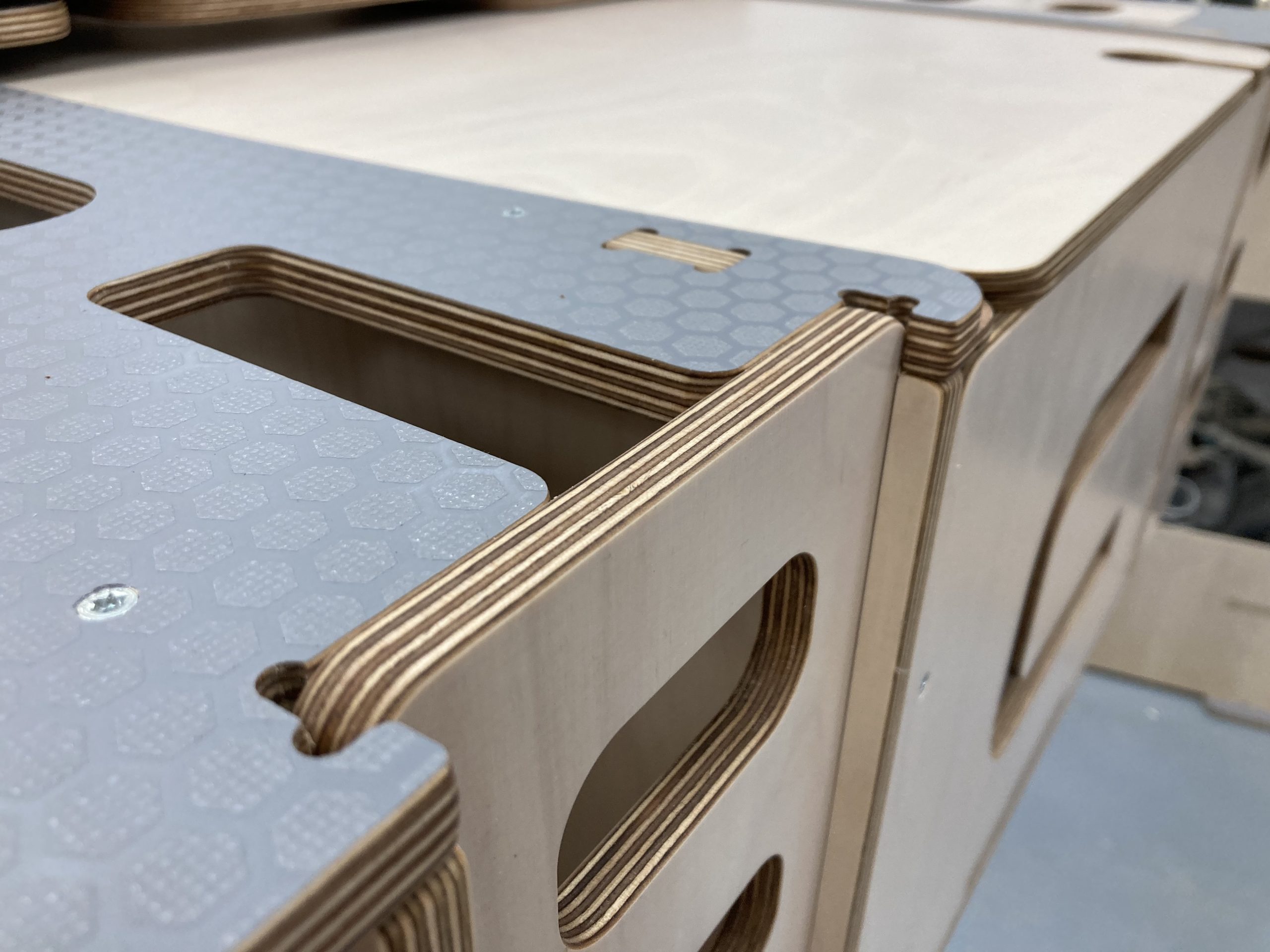

Laser

Birch Plywood with a sanded face on two sides, and an interior glue lining for laser cutting.

Melamine

Birch Plywood overlaid with a white melamine film on both sides. Reverse side can be overlaid with a phenol film.

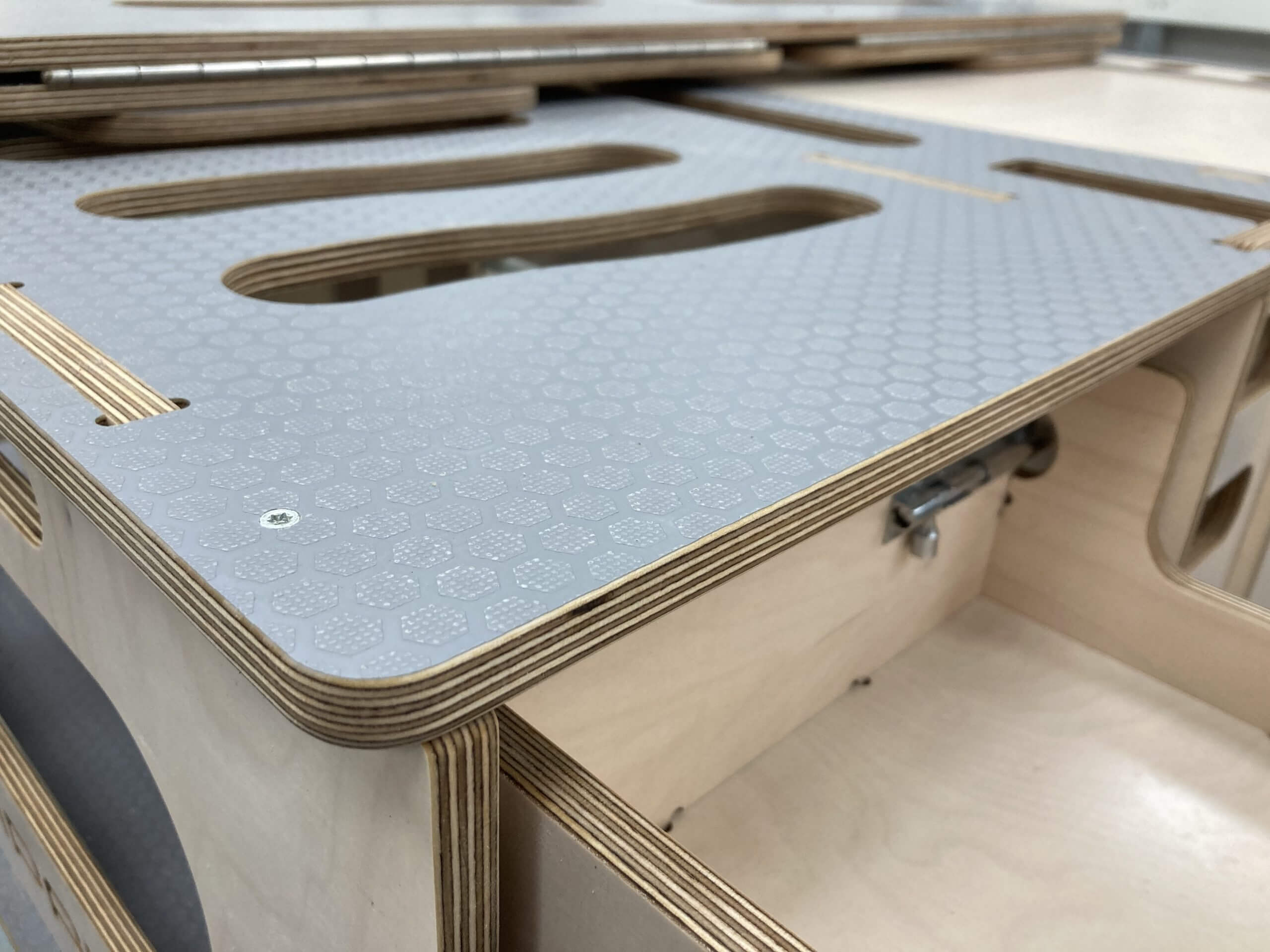

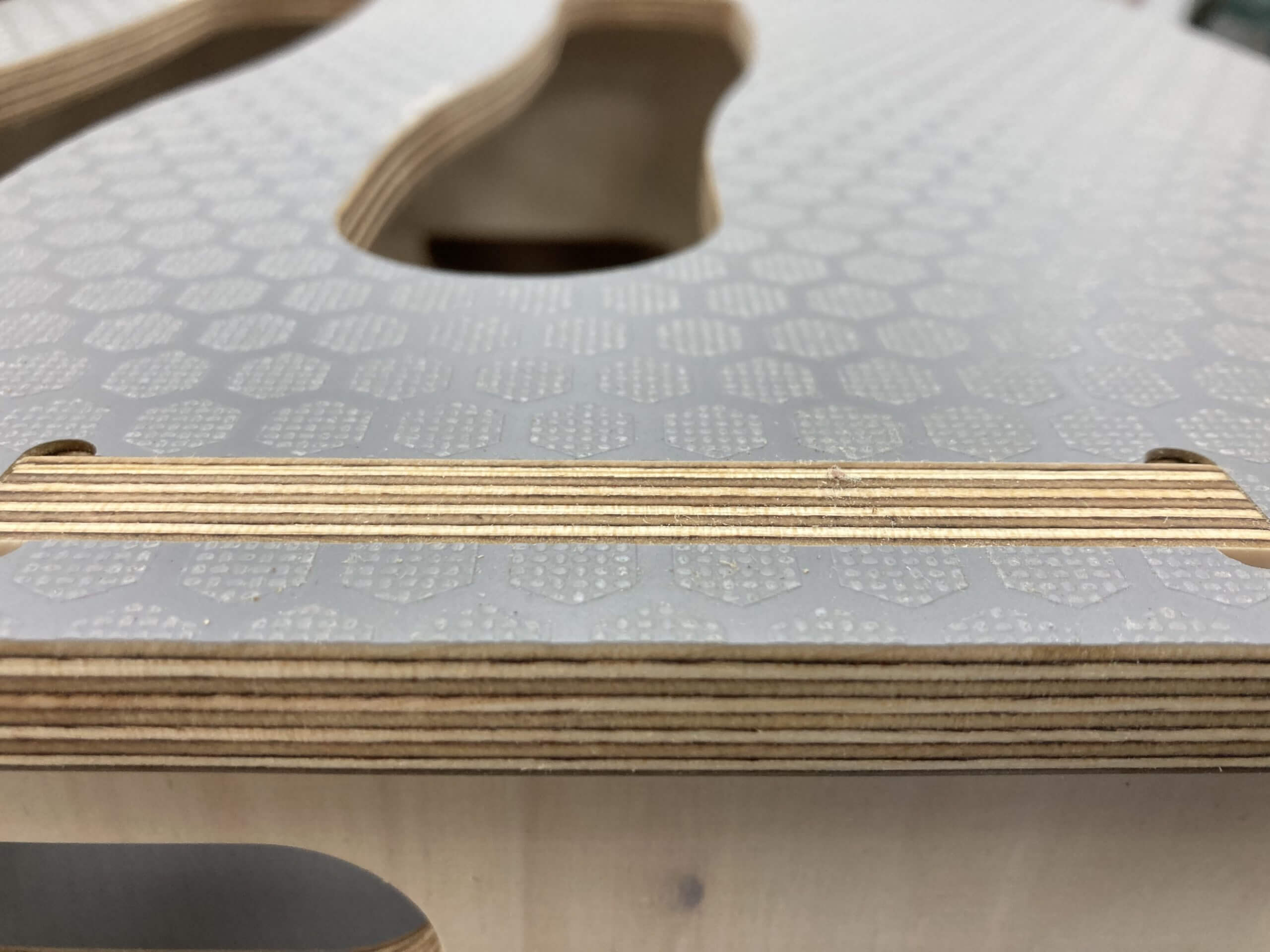

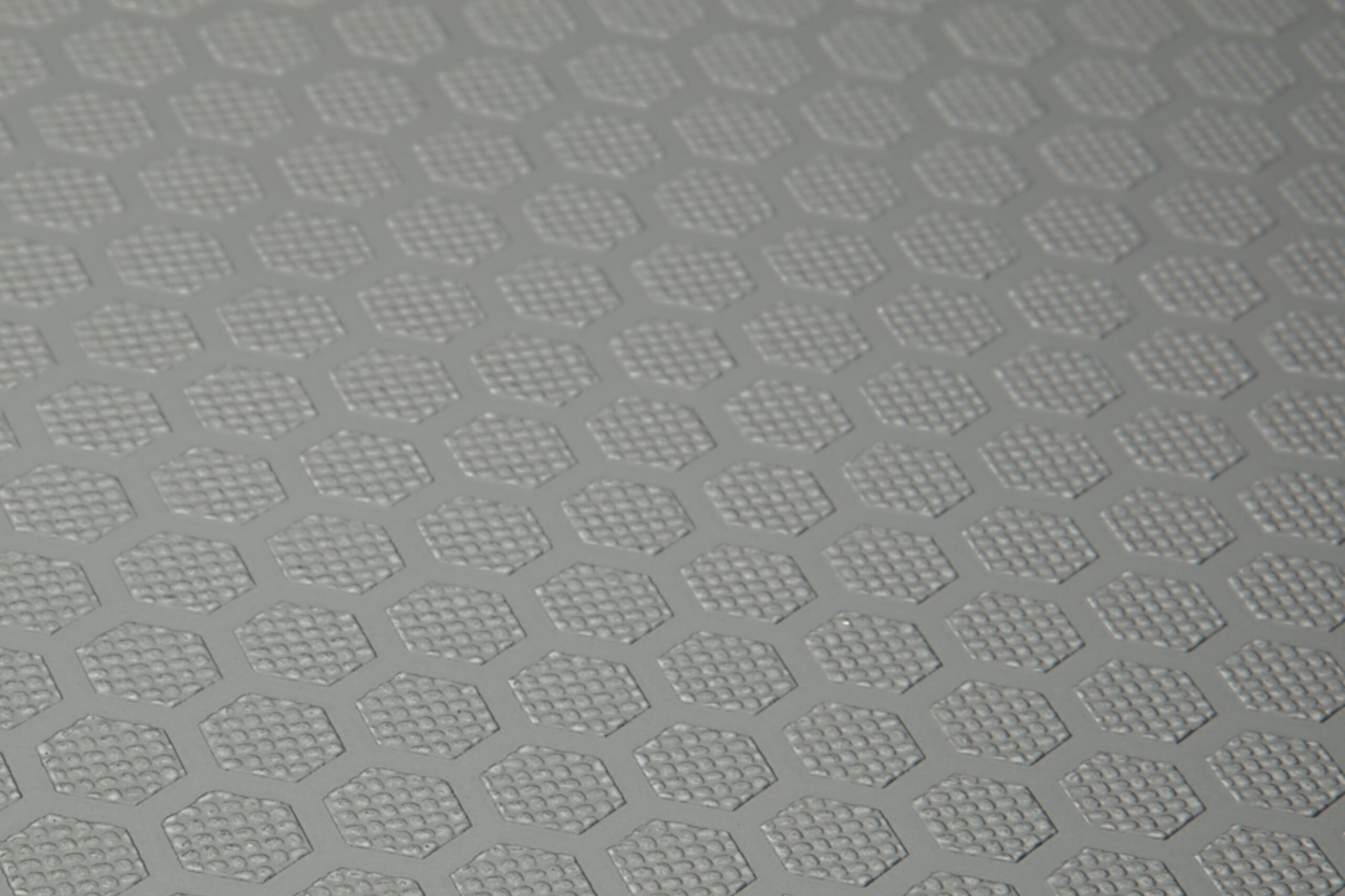

Heksa Plus (Grey)

Birch Plywood overlaid with a phenol film on both sides. Grey hexagonal pattern on wear side; smooth reverse.

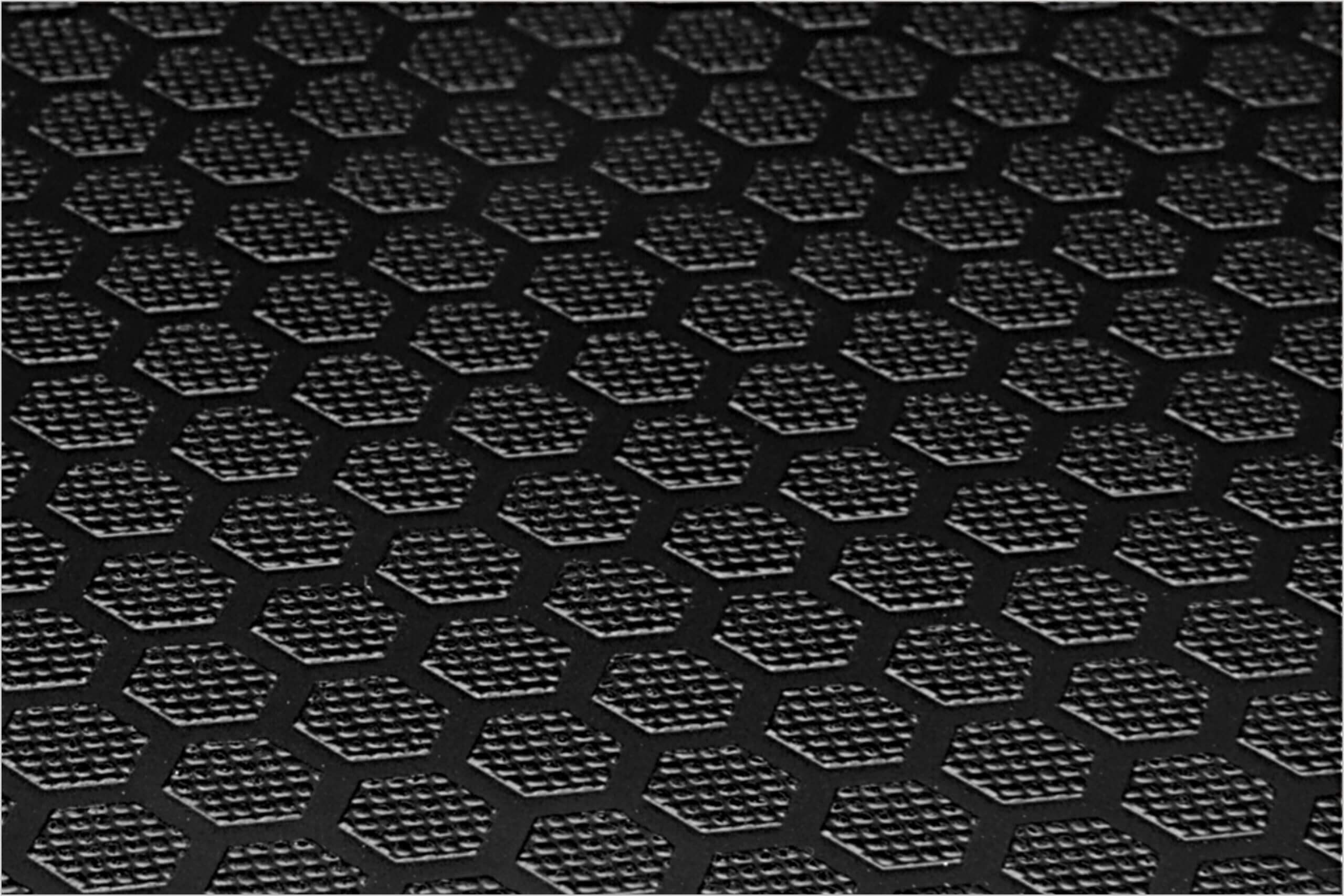

Heksa Plus (Black)

Birch Plywood overlaid with a phenol film on both sides. Black hexagonal pattern on wear side; smooth reverse.

Tex (Black)

Birch Plywood overlaid with a phenol film on two sides. Black textured pattern on wear side; smooth reverse.

Tex (Brown)

Birch Plywood overlaid with a phenol film on two sides. Brown textured pattern on wear side; smooth reverse.

Form (Grey)

Birch Plywood overlaid with a Grey phenol film on both sides. Smooth surface on both sides.

Form (Black)

Birch Plywood overlaid with a Black phenol film on both sides. Smooth surface on both sides.

Form (Brown)

Birch Plywood overlaid with a Brown phenol film on both sides. Smooth surface on both sides.

Form (Opal)

Birch Plywood overlaid with a pinkish/white semi-transparent phenol film on both sides. Smooth surface.

Poliform

Birch Plywood overlaid with a special composite material on both sides that resembles concrete or stone.

Clear Lacquer

Birch Plywood lacquered with a clear layer either one or two sides for interior use. The lacquer is UV cured.

Container

Birch Plywood cross bonded and sanded on both faces using E1 resin glue. Ideal for use as container floors.

FR Euro B

BB Grade Birch Plywood face that has been FR treated to comply with Euroclass B. All knots over 6mm replaced with plugs.

Composite PPL

Birch Plywood overlaid with a polypropylene face. Resistant to chemicals and UV. Also available in White.

Veneered

Birch Plywood overlaid with a wood veneer. Range of veneer faces available on request to suit all client requirements.

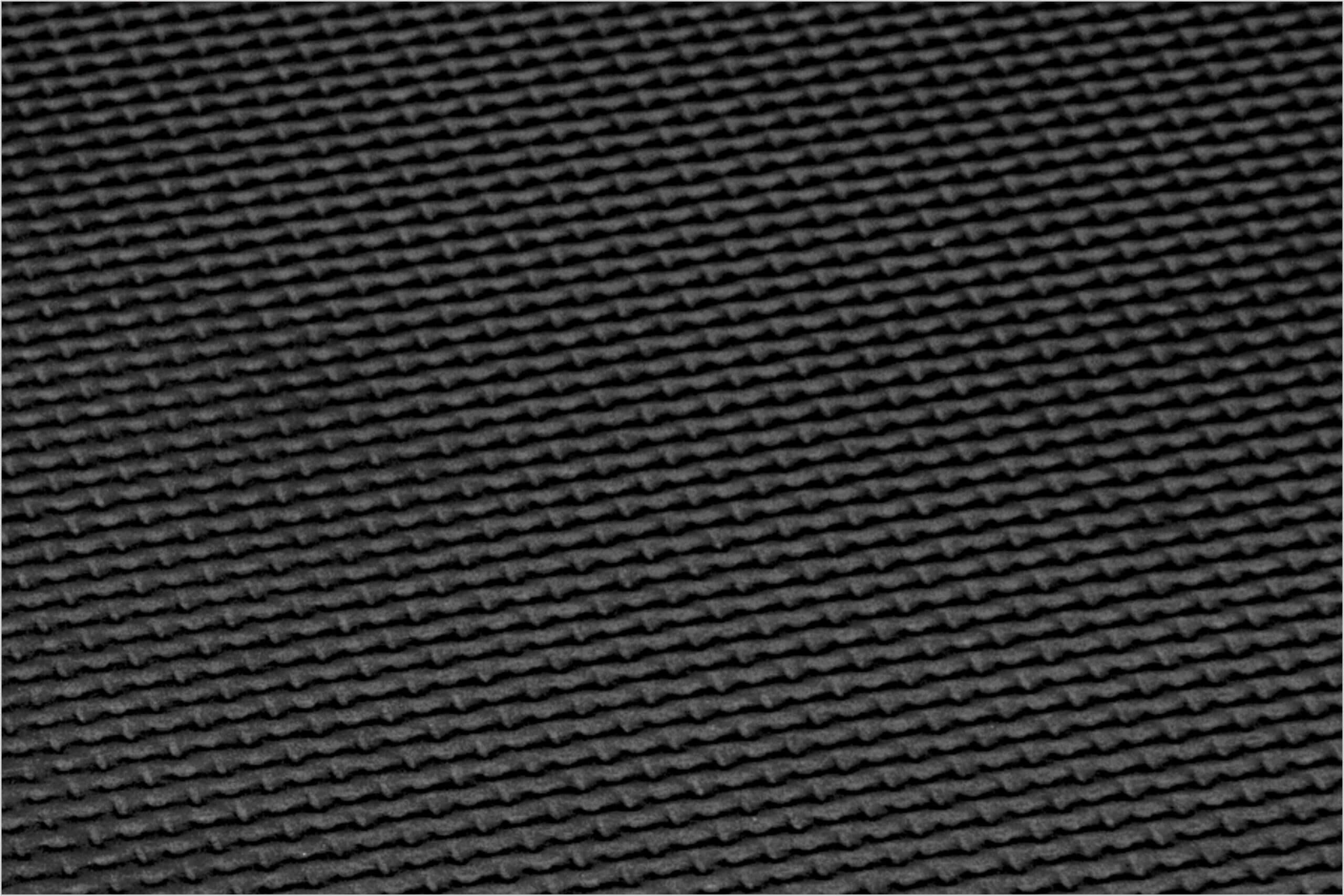

Smooth Mesh

Birch Plywood overlaid with a phenol film on both sides. Smooth wire mesh on one side; smooth reverse.

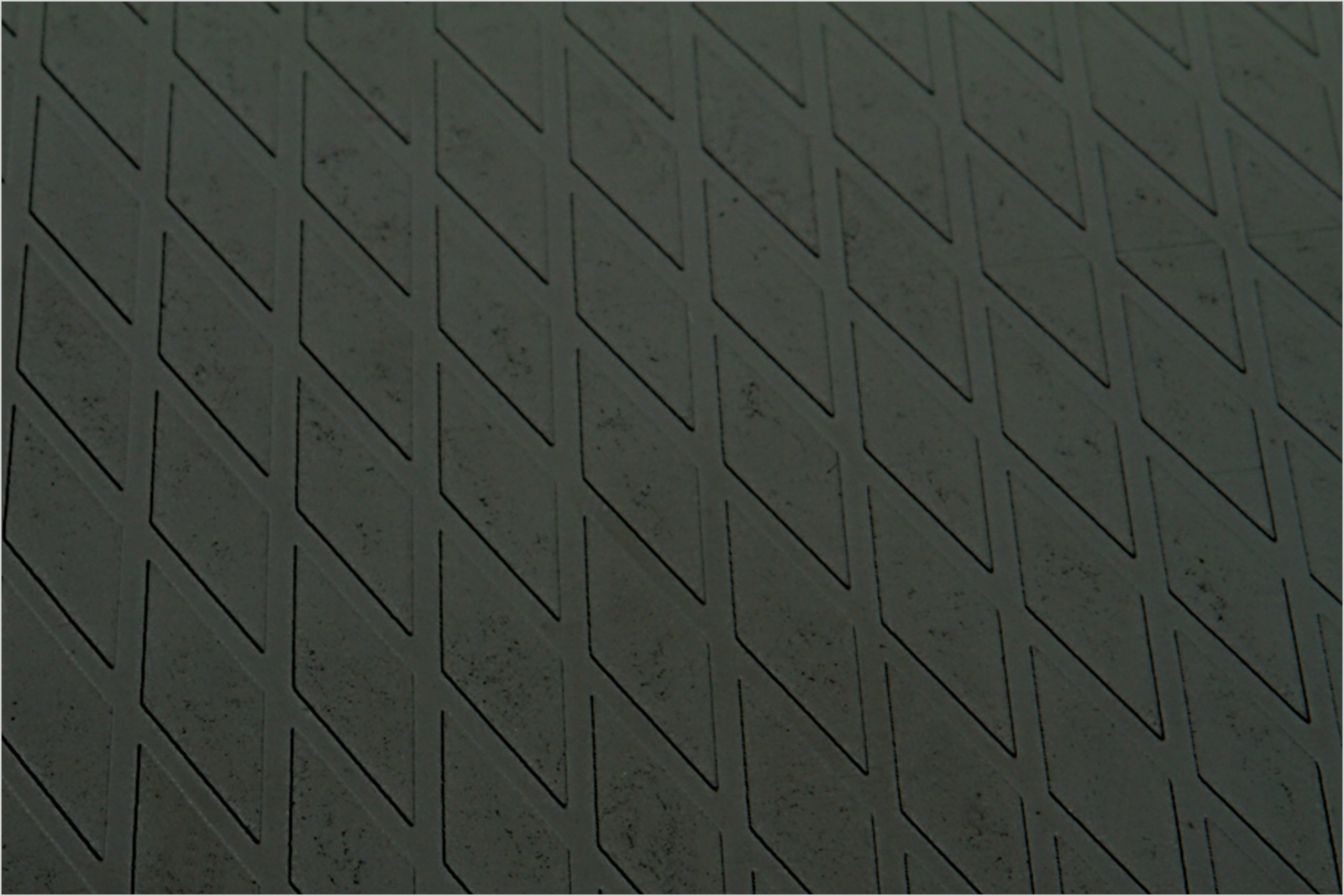

Diamond

Birch Plywood overlaid with a phenol film on two sides. Large diamond pattern on wear side; smooth reverse.

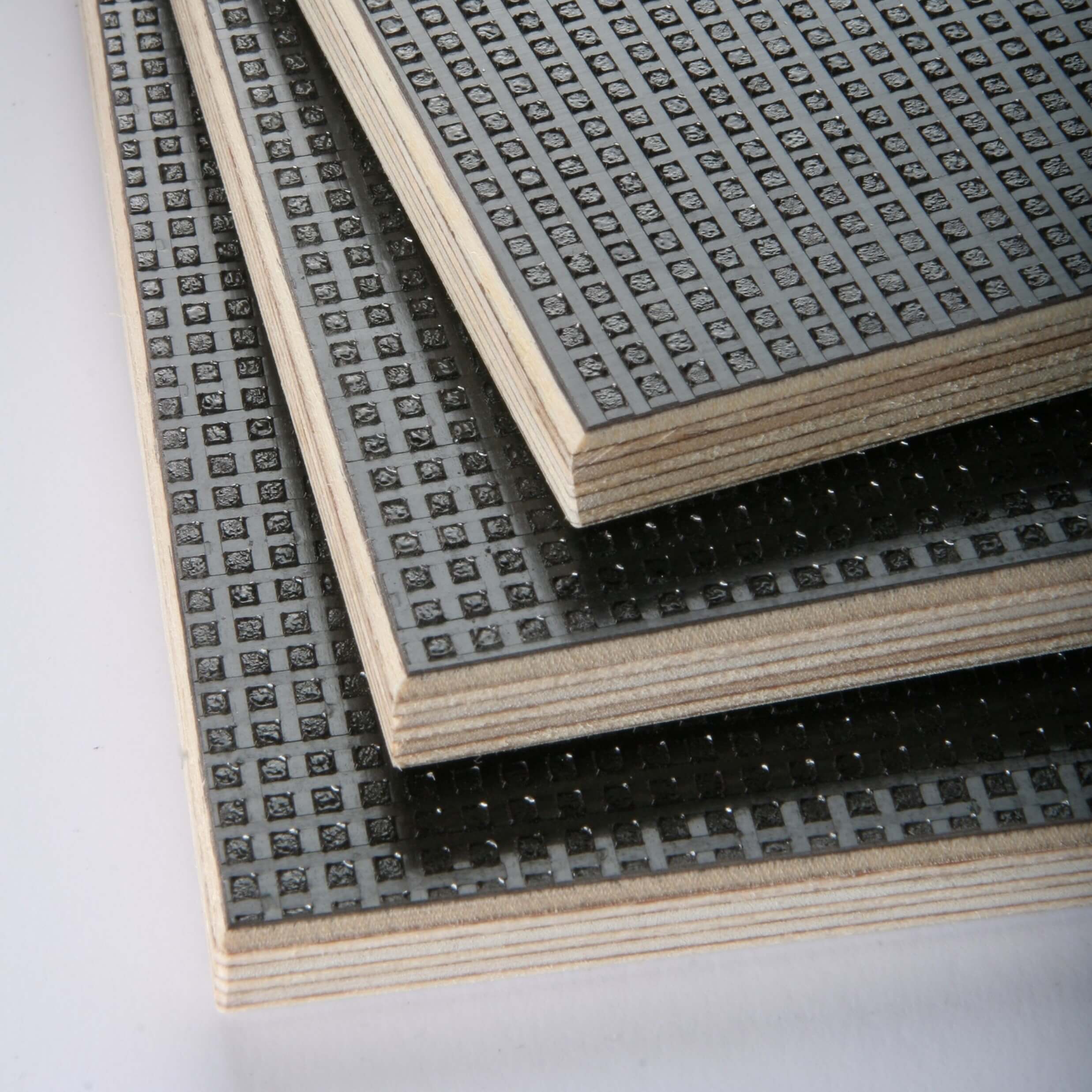

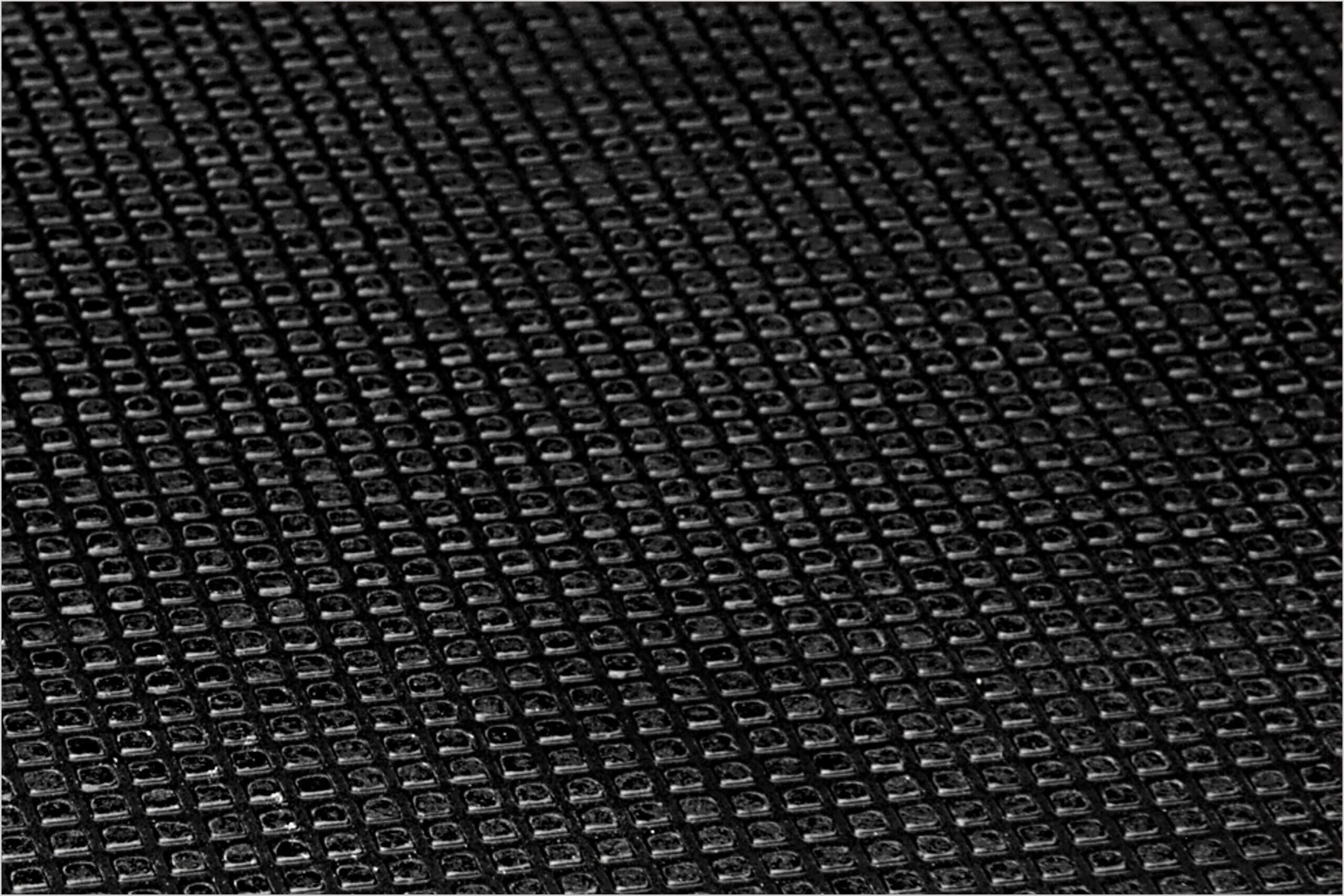

Trans

Birch Plywood overlaid with a dark brown phenol film on both faces. Square pattern on wear side; smooth reverse.

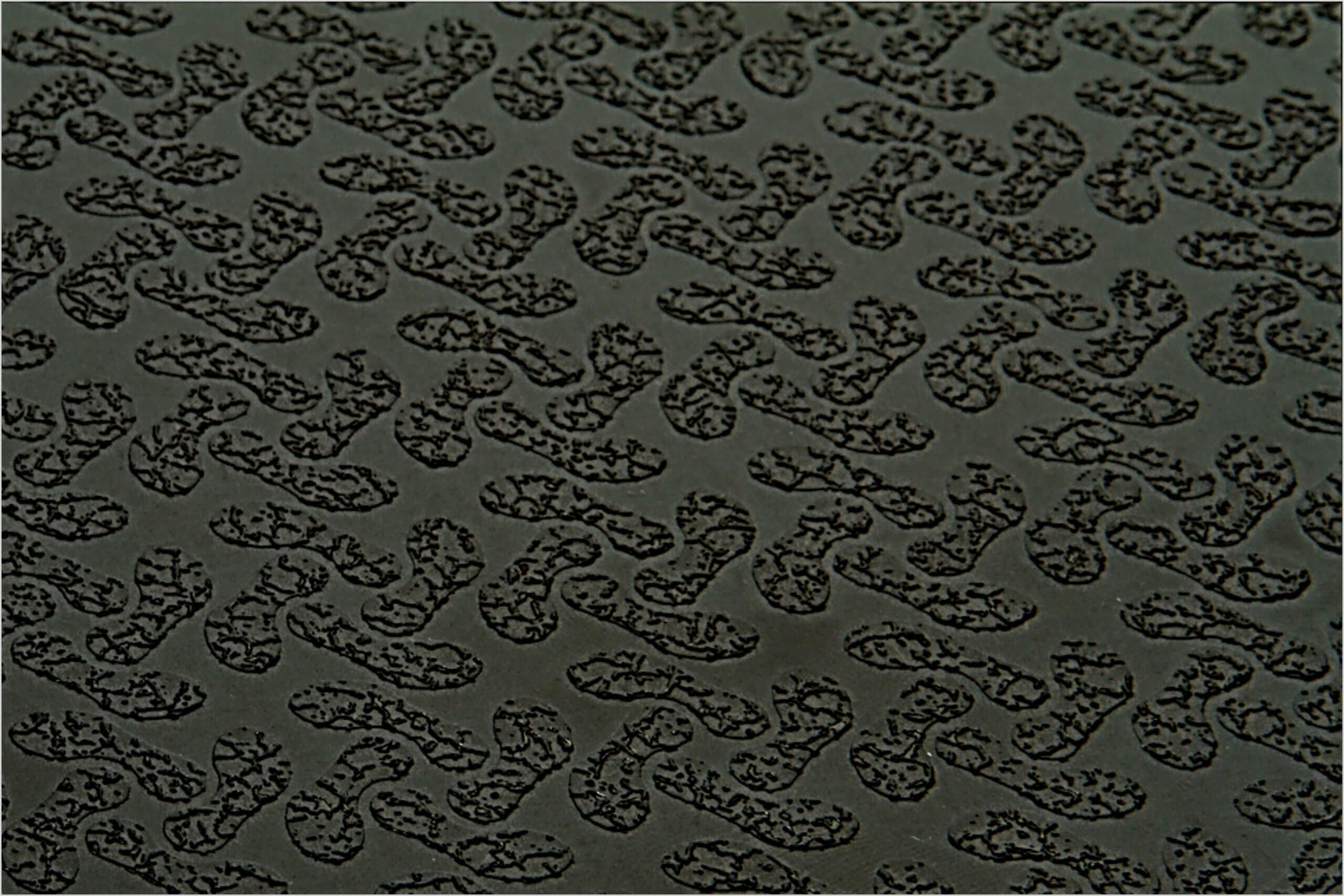

Foot

Birch Plywood overlaid with a phenol film on two sides. Footprint pattern on wear side; smooth reverse.

HPL

Birch Plywood overlaid with a white HPL laminate face on both sides. Balance paper can be applied on reverse face.

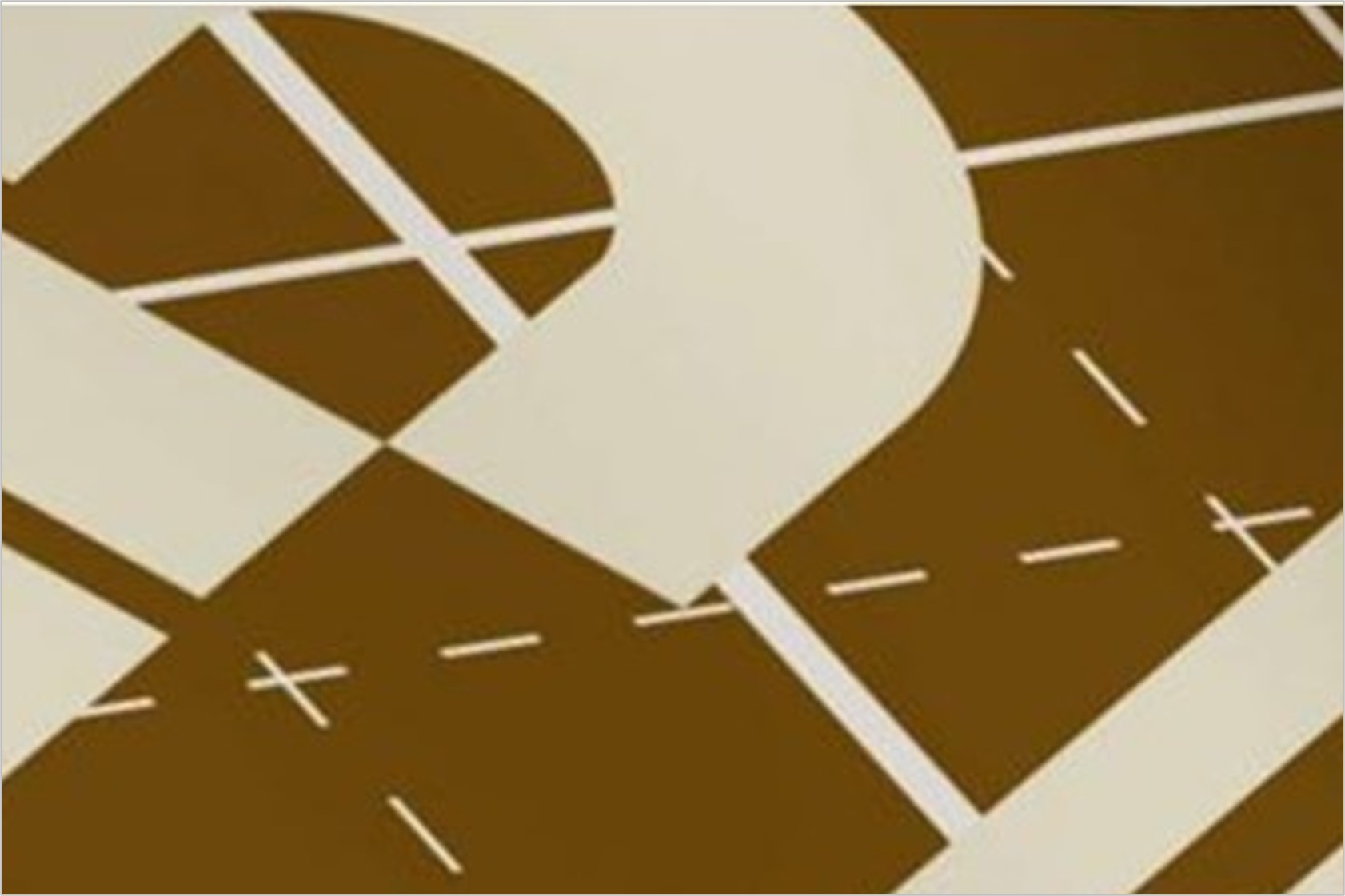

Deck

A special Birch film faced ply intended for slab formwork. It comes with 25, 50 & 100mm grid patterns.

Paint

Birch Plywood overlaid with a painting film on the one or both sides, providing a panel surface suitable for painting.

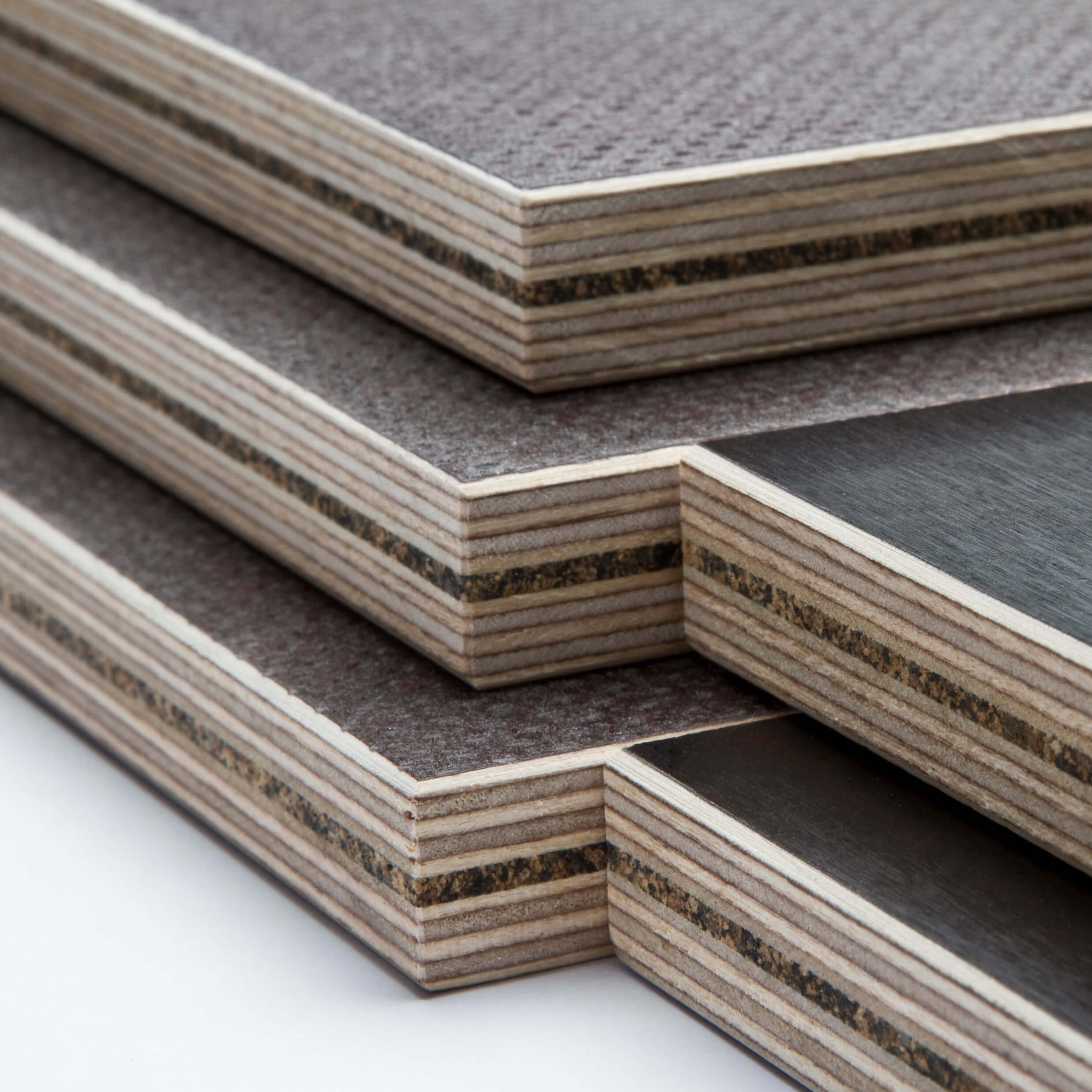

Sound

Birch plywood with cork-rubber composite material core that protects against noise, and dampens vibration.

| Origin: | Europe |

| Species: | Birch |

| Category: | Plywood |

| Formaldehyde Level: | E1 |

| Interior Use: | Yes |

| Exterior Use: | Yes |

| CE Standard: | CE2+ |

| Density: | 650+ Kg/M3 |

| FR Rated: | B* |

| MR rated: | Yes |

| FSC® Certified: | Yes |

| PEFC™ Certified: | Yes |